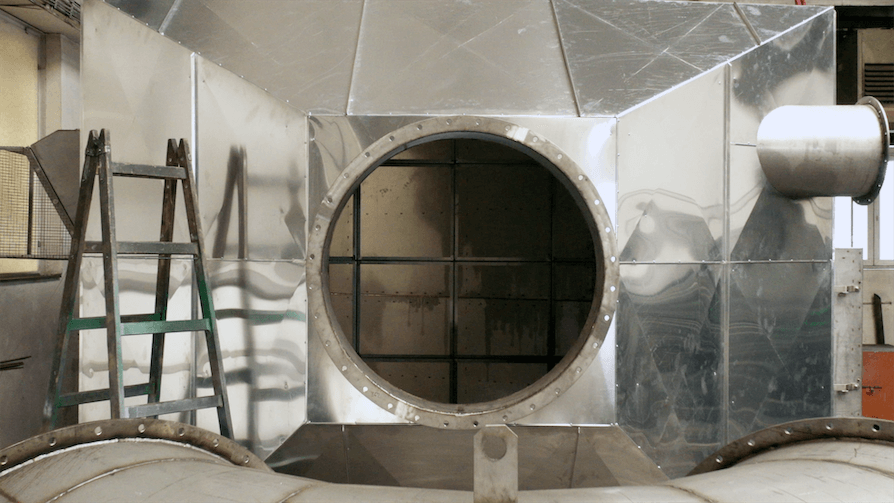

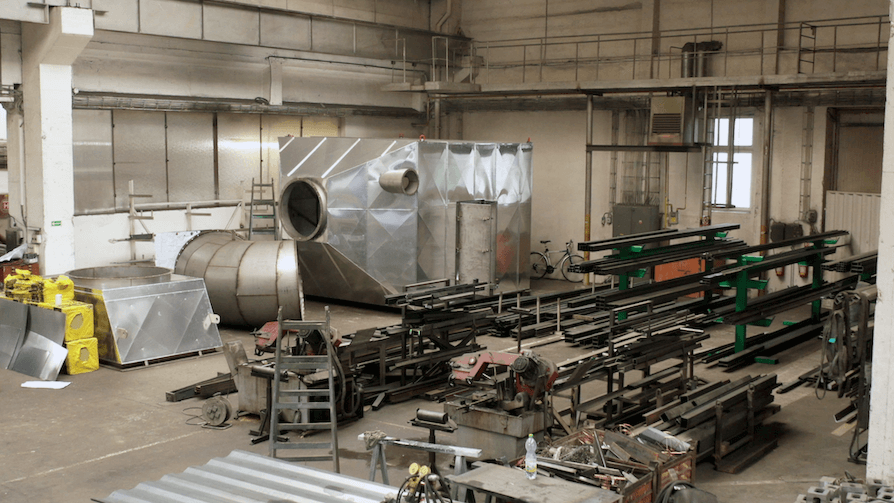

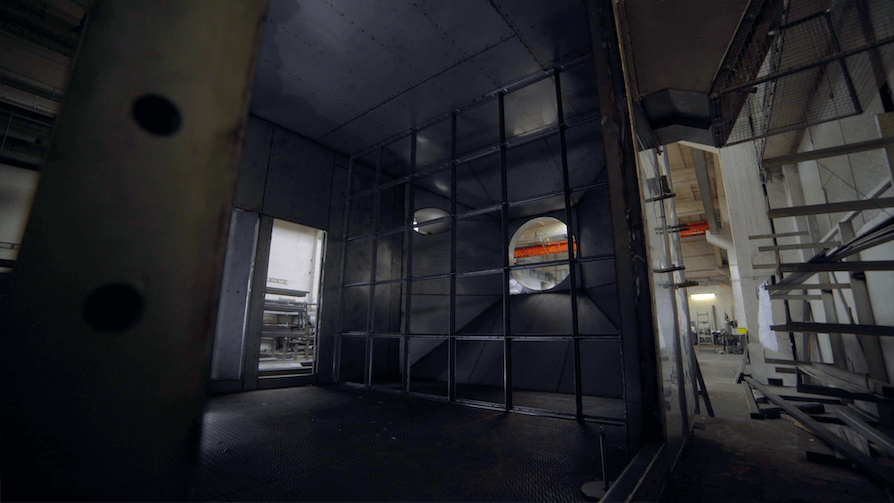

Industrial Filtration units (oxidizer RTO)

Production of filtration units

Filtration units are essential for air purification, especially in industrial plants. Volatile organic compounds formed in paint shops, pharmaceutical plants, engineering, metallurgy, rubber industry, printing, petrochemistry, glass and jewelery production need to be regulated and eliminated. Other such substances include industrial chemicals, solvents, alcohols and petroleum products. Filtration units, which have the character of all-metal constructions, can burn polluted air at high temperatures (ie above 800 ° C) and then filter it. They are therefore also used in brickyards and in plastics or food (eg dog food) production plants. Furthermore, in any production where solids are released into the air.

Technologies that can be used for the purification of industrial air and the recuperation of organic solvents, either by catalytic or thermal combustion, make it possible to reduce the volume of this polluted air (usually before entering the incinerator).

For the technologies of catalytic and thermal oxidation of volatile organic compounds (VOC) - thermal, catalytic, regenerative (RTO) and recuperative (TO) processes, our production provides:

- steel structures of combustion filter units

- steel structures for placing pocket air filters

- circular shut-off dampers for air ducts (for duct diameters from 700 mm to 1600 mm and temperatures up to 900 ° C)

The quality of deliveries is certified in accordance with the ISO 9001: 2008 and ISO 14001: 2004 standards.